Experience a different level of product power produced with industry-leading technology.

Snowbahn, a global luxury snowflake shaved ice machine

The reason why Snow Barn has risen to a unique position.

Meet the upgraded 2024 Snow Barn.

It has become more convenient by significantly reducing the inconveniences that arise during use.

Experience a smarter user-centered design.

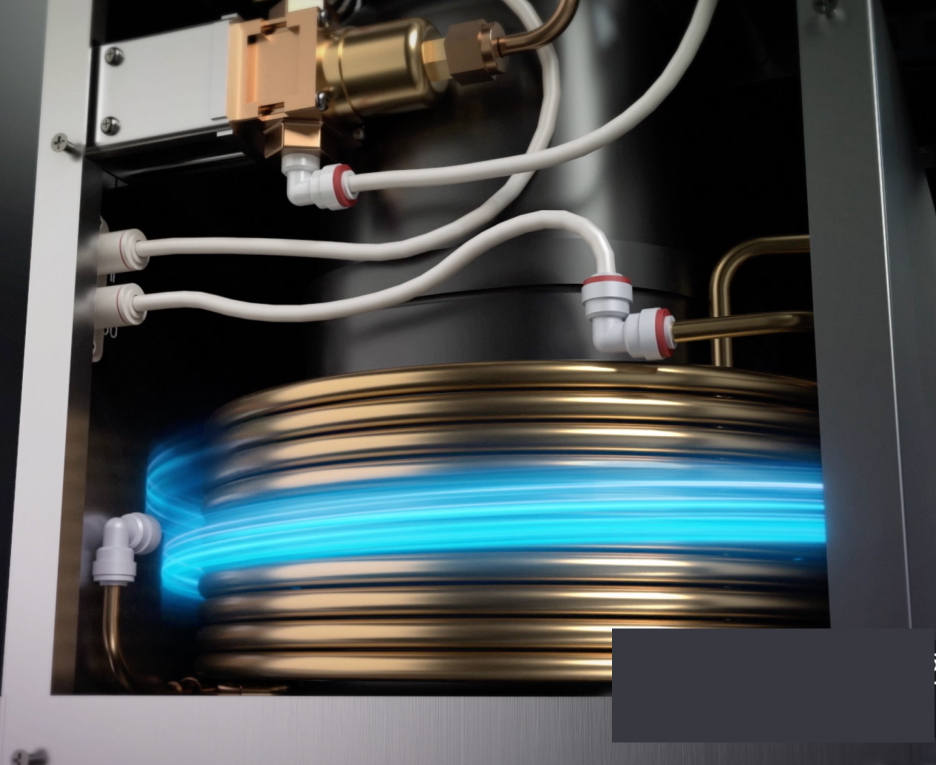

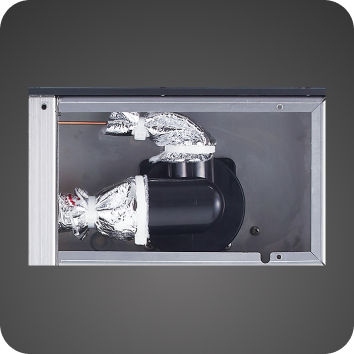

Drum cooling method

Equipped with water-cooled/automatic water-saving valve

44kg

W295

310kg/day

1,300W

PC (Poly Carbonate)

JH071043-22001

Drum cooling method

Equipped with water-cooled/automatic water-saving valve

44kg

W295

310kg/day

1,300W

PC (Poly Carbonate)

JH071043-22001

raw material container

raw material container  drum plate

drum plate  vacuum tube rod

vacuum tube rod  raw material valve

raw material valve  drum

drum  ice making blade

ice making blade  Gas leak prevention shaft

Gas leak prevention shaft  housing

housing  Condensation prevention cover

Condensation prevention cover  Noise/Vibration

Noise/Vibration Drum reservoir to prevent raw material overflow

Experience completeness with a failure rate of 1% or less.

It has been tested non-stop 24 hours a day for more than a year and thoroughly verified.

Detailed.

From antibacterial to raw material loss rate.

The greatest achievement in shaved ice machine history.

A specialized ice maker company that has quietly followed the same path for over 30 years.

Until it was called a luxury device,

To meet the ever-increasing expectations of consumers

This is the result of a thorough focus on market research, customer needs, and customer reviews.

Compare and choose.

Custom made (injection molded) accessories.

All products/parts are produced and shipped with high quality.

Solidity without gaps.

PC (Poly Carbonate) material and

Sturdy, thick stainless steel.

third party

Accessories made from ready-made or bent sheet metal.

Presence of sharp external parts.

Injecting foreign substances into small gaps.

Plastic and stainless steel materials.

The difference in cooling power can be felt only when used.

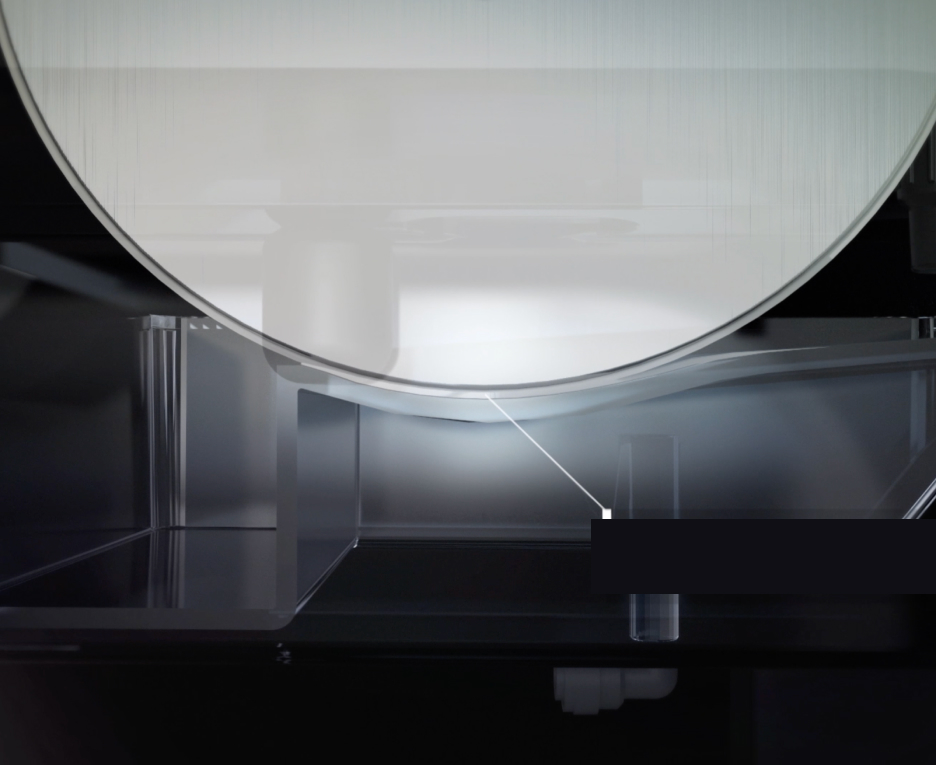

The only thin drum thickness in Korea, the optimal thickness.

Efficient cooling power, minus 50 degrees without pre-cooling.

Soft and fluffy ice, ice that does not melt easily and lasts for a long time.

Using water-cooled heating method:

Coolant is used to cool down the heat inside the machine.

It is not affected by ambient temperature or humidity.

Cooling efficiency maintained even during long-term use/Basic cooling power - high

third party

Cooling power is unstable due to thick drum.

Rapid cooling ability decreases, -25 to 35 degrees below zero after pre-cooling.

The ice quality is not consistent, whether it is muddy or soft.

Heating method – air-cooled/water-cooled.

The air-cooled heating method uses the wind from a fan to cool down the heat.

When the surrounding temperature is high, such as in summer, the ice-making ability decreases.

Cooling power is limited/Basic cooling power is low.

Implementation of a different level of ice quality.

Use of high-hardness stainless steel blades (3rd processing).

Ultra-precision processed cooling drum and blade provide detailed ice quality.

Stable, continuous production with uniform ice quality even during long-term production.

third party

Use of regular stainless steel blades (primary processing).

Irregular snowflake/ice shape.

Easy and simple to operate.

Simple and convenient one-button switch method.

Immediate start > Immediate stop > Immediate restart:Waiting time 0 seconds

Mechanical button with excellent stability.

Focusing on user-oriented convenience functions (ON/OFF/drum idling)

third party

Touch or dial type with PCB mainboard.

Start > Stop working after 1 minute > Restart immediately: Waiting time 30 seconds

Poor contact, frequent AS occurrence.

Incomplete method where you touch and hold the button for a few seconds depending on the function.

The presence or absence of a water-saving valve that automatically controls coolant.

Adoption of high-performance and high-quality automatic coolant adjustment and control device.

Reduce water bills by using the optimal minimum amount of cooling water.

Immediate response to changes in water temperature and pressure.

Maintains uniform ice quality even during long-term operation.

Optimized for various environments, including overseas and seasons.

third party

No coolant regulator

Manual control device only has coolant on/off function

Unable to respond to changes in water temperature and pressure

Uneven ice quality production during operation

The quality of ice produced varies depending on the water temperature (differences occur in summer/winter).

There are also overwhelmingly unexpected details.

Injection mold production with ultra-tight structure that matches the drum shape.

There is almost no remaining solution, less than 1ml.

No cleaning required when converting the concentrate.

Raw material container with added antibacterial function. Prevents and prevents bacterial growth 99.9%.

Easy cleaning with drum idling function.

A structure that allows hands to reach every corner.

Fine parts can be separated and cleaned.

third party

Drum plate made of stainless steel.

Within 80ml of remaining concentrate.

When converting the concentrate, material costs are lost and cleaning time is required.

Bacterial growth is possible when using dairy products or powders.

Auto-cleaning function Hygienic cleaning not possible

Reduced drum cooling capacity when using steam

Parts cannot be separated (unhygienic)

You have to look at the parts to make it real.

Can be used semi-permanentlyOne high-performance gas leak-proof shaft.

Improved housing performance.

Dissolvable designThis enables quick processing when AS occurs.

Only 70% of capacity is driven stably with 1 horsepower.

No increase in pressure even when stopping without braking time.

Compressor specialized for snow barn.

Reduced by 50% compared to before.

third party

Gas leak-proof shaft requiring periodic replacement.

Shafts that require frequent charging of refrigerant gas due to leakage.

Due to welding process, repair time is required in case of after-sales service.

Due to the high gas pressure difference when stopping immediately

Requires braking time and waiting time.

Tremors and noise occur.

In the case of air-cooled type, there is noise and dust blowing from the fan.

From demonstrations to recipes.

Before and after purchase

We will guide you in the optimal direction.

Fastest installation and delivery.

Professional personnel from the head office installation team

We will arrange it immediately.

Reliable AS.

To avoid damage to business

We help you with quick and accurate after-sales service.

There is also a Snowbahn Mini that is easy to use.

The Mini, which was designed to be more compact and simple to use, does not contain a large amount of shaved ice or

Perfect for stores looking to add to their assortment or for home or personal use.

| size | W280 Height including raw material container 545mm |

|---|---|

| Ice cooling method | Drum cooling method |

| Ice quality that can be produced | Snow Flower |

| production speed | Approximately 2 minutes 10 to 30 seconds based on 200ml of milk |

| Create snowflake | 10 to 15 seconds after operation / No pre-cooling required |

| drum width | Drum width 6.5cm, can be received directly in bowls of various widths |

| loss rate | Within 20ml of remaining concentrate |

| output | Daily output 160kg |

| Power Consumption | 700w |